Trimmer carburetor adjustment - brush cutters

Gas mowers, like all gas mowing tools for mowing grass, are not considered difficult to maintain equipment. They can and should be set up, repaired with their own hands. So, for example, in five minutes of your free time, you can adjust the trimmer carburetor. Often, to adjust the engine, you need to adjust the gas supply, and this is done precisely by the carburetor of the mower. Such a device requires special attention. If used improperly, it may refuse to work or will perform its functions with errors and with high power consumption. Today we will analyze the main causes of failure and step-by-step adjustment of the part with our own hands.

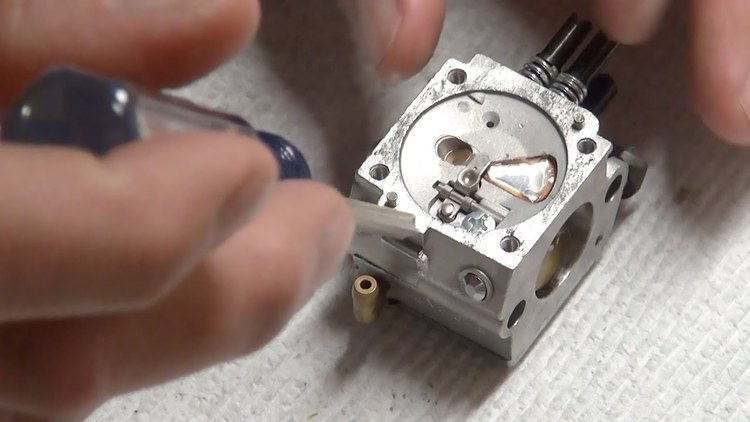

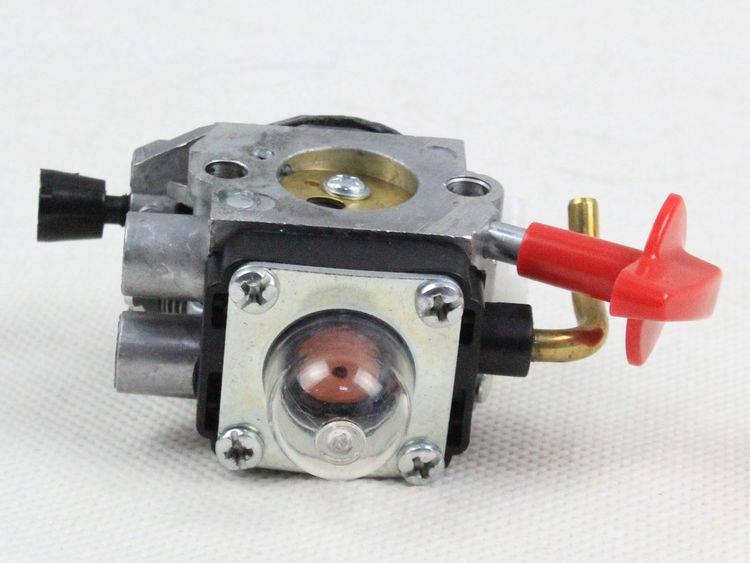

to contents ↑How is the mower carburetor designed?

What is a carburetor? This is a complex part in the system of operation of a mechanical device. In any model, air and gas are mixed for future supply to functioning cylinders.

Important! The most high-quality and recommended gas scythes can be safely called the devices of such brands: Husqvarna, Hyundai, Stihl, Zama, Walbro.

At the heart of the engine of the brushcutter is an aluminum base, which has a diffuser (a recess with internal restrictions). It is through this recess that the air currents are heated. The oxygen delivery rate directly depends on the passage of the diffuser.

Fuel paths are adjacent to the diffuser. Gasoline is drawn in through it through the air stream. But on the outside of the engine, the following parts are installed:

- Fuel pump.

- Jet system.

- The system for adjusting the ratio of gasoline to air.

to contents ↑Important! The air density in the carburetor depends on the volume of the flap open to access. The more the damper system is open, the more the unit consumes gasoline and the higher its power. That is, setting the carburetor on the trimmer is to create the optimal fuel intake due to the correct air supply.

When do I need to adjust the carburetor in the trimmer?

You need to configure the device in such cases:

- The new engine used 5 liters of fuel mass in one go.

- The weather has changed (a sharp drop in atmospheric pressure).

- You bought another brand of oil or gasoline.

- During prolonged storage.

- After vibration, the screws unscrew themselves.

- The consumption of gasoline increased, the carburetor began to pour fuel.

- The appearance of carbon deposits on the electrodes of the inner candle of the device.

- Gas stopped flowing into the cylinders.

- The motor often stalls or does not gain enough speed.

What are the failures and how to recognize them?

One of the problems with the failure of the trimmer engine can be a strainer. Only two breakdowns can be attributed to this element:

- The accumulation of dust and dirt.

- Partial or complete failure.

To identify the exact cause, you need to do a number of the following:

- Unscrew the cover of the fuel air lock to remove the strainer. If dirt is found on the part, rinse it with fuel or blow it thoroughly. If you see serious damage to the filter housing, without hesitation you need to install a new one.

- If the pipe for supplying compressor fuel is broken, then check this part. Most often, it requires periodic replacement due to its low strength.

- To clean the starting part of the carburetor from blockages, you need to use acetone or gasoline. You can also blow component parts with compressed air - this is the easiest and most convenient way to repair.

to contents ↑Important! The throttle base, intake and exhaust valves, the joints of all carburetor parts can be checked with a simple action - grease the problem area with soap foam.

Self-adjusting carburetor trimmer

Before setting up the device, we recommend that you do the following:

- Clean and flush the engine.

- Check the spark plug for suitability.

- Remove dust and dirt from the air filter or change it to a new one.

- Put a cord suitable for the diameter in the trimmer roller or install well-sharpened knives.

After installing the cutting parts and starting the fuel engine, the carburetor needs to warm up for 10 minutes. If the cutting tool rotates while the engine is idling, reduce the engine speed.

Adjusting the carburetor on the trimmer is a difficult and time-consuming job. To correctly configure it, you will have enough information from our informative article. And to do everything accurately, use the video, which clearly shows the whole process.

- How to choose a vacuum cleaner taking into account the characteristics of the house and coatings?

- What to look for when choosing a water delivery

- How to quickly create comfort at home - tips for housewives

- How to choose the perfect TV - useful tips

- What to look for when choosing blinds

- What should be running shoes?

- What useful things can you buy in a hardware store

- Iphone 11 pro max review

- Than iPhone is better than Android smartphones